Sewer Pipe Burst

Pipe bursting is a trenchless method of replacing damaged or worn-out underground pipes without the need for traditional excavation techniques. In pipe bursting, a specialized machine is used to break apart the old pipe and replace it with a new one.

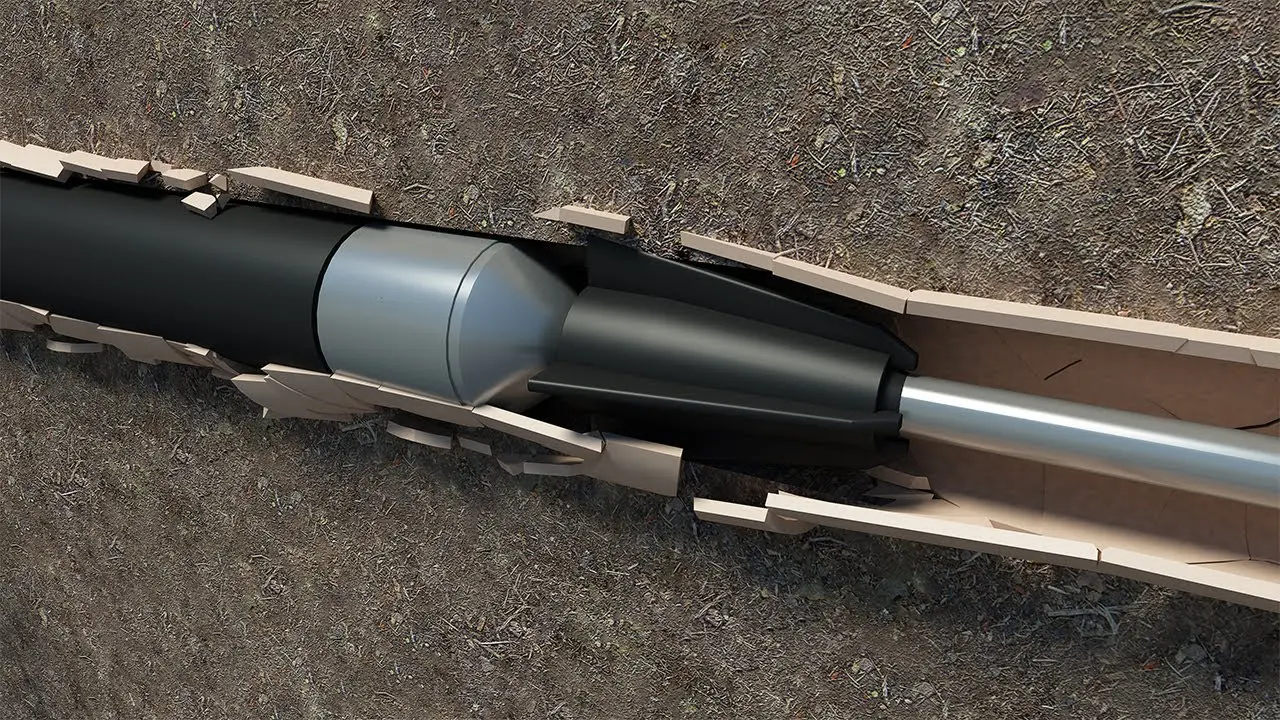

The process involves pulling a cone-shaped bursting head through the existing pipe, breaking it apart and pushing the fragments into the surrounding soil. A new pipe is then pulled through the same path, replacing the old pipe and restoring the flow of water or sewage.

Pipe bursting is typically used to replace pipes made of materials such as clay, concrete, or cast iron that have deteriorated over time or been damaged by tree roots or other factors. It is often preferred over traditional excavation methods because it is less disruptive to the surrounding environment, requires less time and labor, and can be completed with minimal disruption to surface areas such as driveways, sidewalks, and landscaping.

However, pipe bursting is not suitable for all situations, and its success depends on factors such as the condition of the existing pipe, soil conditions, and the location and depth of the pipes. It is typically carried out by trained professionals and requires specialized equipment, so it is not a DIY project.

When should you Pipe Burst versus other Trenchless Repairs?

The decision to use pipe bursting versus pipe lining will depend on several factors, including the condition of the existing pipe, its location, and the goals of the repair or replacement project.

Pipe bursting is typically used when the existing pipe is severely damaged or deteriorated and needs to be completely replaced. This method is particularly effective for pipes that have collapsed, have significant cracks or holes, or are made of brittle materials such as clay or concrete. Pipe bursting is also useful when the diameter of the new pipe needs to be larger than the existing pipe, as the bursting process can accommodate a wider range of pipe sizes.

Pipe lining, on the other hand, is typically used when the existing pipe is still structurally sound but has minor cracks, leaks, or other defects that need to be repaired. This method involves inserting a flexible liner into the existing pipe and curing it in place, creating a new pipe within the old one. Pipe lining is often used for pipes made of materials such as PVC, ABS, or cast iron that are in relatively good condition.

In general, pipe bursting is more invasive and disruptive than pipe lining, as it requires digging access pits at each end of the pipe and can cause more disturbance to the surrounding area. However, it is often a more cost-effective and efficient solution for severely damaged or deteriorated pipes, as it eliminates the need to excavate and remove the old pipe. On the other hand, pipe lining is typically less expensive and less disruptive for minor repairs and can extend the life of the existing pipe.